| SUITBLE FOR |

| GASES |

AIR |

STEAM |

OIL |

WATER |

|

|

|

|

|

|

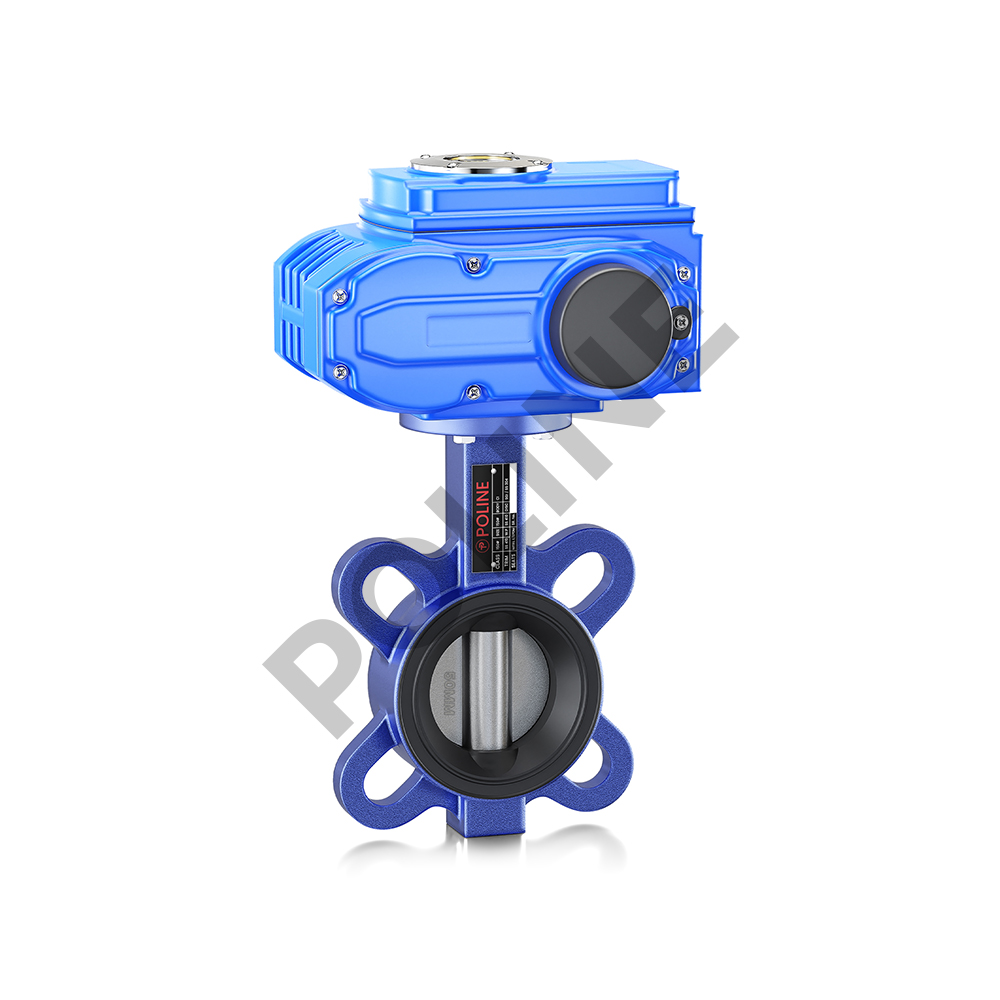

Salient Features

- Design Standard IS 13095. Wafer Type

- Electrical Acuator Operated

- Stainless Steel Disc which Is Accurately Guided Between The Two steams

- Integrally Moulded Rubber lining

- Actuator is With Position Indicator and Adjustable Center Stopper for Both Open and Closed Position

- Compliant with B.M.S (Building Management System)

- Can Be Provided with Extended Wire For Ease Of Installation

- IP 67 Protection Available for Outdoor Application

- Inbuilt Micro Switch Position Feedback

- Input Voltage - 24/230 V Power Supply

- Compatible to Sandwich Between Flanges as per BS 10 Table D,E,F ASA Class 150

Technical Data

- Test Pressure (Hydrostatic):

- Shell: 2.4 MPa

- Seat: 1.76 MPa

- Maximum Working Pressure: 1.6 MPa

- Maximum Working Temperature: 90°C

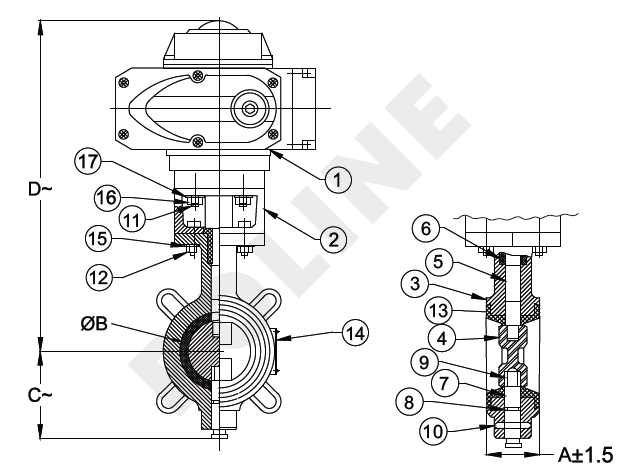

| MATERIAL LIST |

| P.NO |

Name Of Part |

Material of Constuction |

Specifications |

Qty. |

| 1 |

Electrical Actuator |

- |

- |

1 |

| 2 |

Actuator Base |

Carbon Steel |

- |

1 |

| 3 |

Body |

Cast Iron |

IS 210 FG 200 |

1 |

| 4 |

Disc |

Stainless Steel |

IS 3444 Gr.1 / ASTM A351 Gr.CF8 |

1 |

| 5 |

Upper Stem |

Stainless Steel |

IS 6603 Gr.12 Cr 12 |

1 |

| 6 |

Packing Bush |

Bronze |

IS 318 Gr. LTB 2 |

1 |

| 7 |

Lower Stem |

Stainless Steel |

IS 6603 Gr.12 Cr 12 |

1 |

| 8 |

'O' Ring |

Nitrile Rubber |

IS 5192-1 |

1 |

| 9 |

Bush |

PTFE |

BS EN 12086-1 |

1 |

| 10 |

L-Key Screw |

Carbon Steel |

- |

1 |

| 11 |

Studs for Actuator |

Carbon Steel |

- |

4 |

| 12 |

Locking Washer |

Spring Steel |

- |

1 |

| 13 |

Body Lining |

EPDM/ Nitrile |

IS 5192-1 |

1 |

| 14 |

Name Plate |

Aluminium |

- |

1 |

| 15 |

L-Key Bolts & Nuts |

Carbon Steel |

- |

4 Each |

| 16 |

Nuts |

Carbon Steel |

- |

4 |

| 17 |

Spring Washer |

Spring Steel |

- |

4 |

|

SIZE / DIMENSIONS

|

| Size(mm) |

A+1.5 |

B |

OC |

OD+5.0 |

E(MAX.) |

The information provided here serves as guidelines only and is subject to possible modification.